OEM Factory for Tearing Fixture - Electro hydraulic servo dynamic fatigue testing machine – Enpuda

OEM Factory for Tearing Fixture - Electro hydraulic servo dynamic fatigue testing machine – Enpuda Detail:

APPLICATION AREA

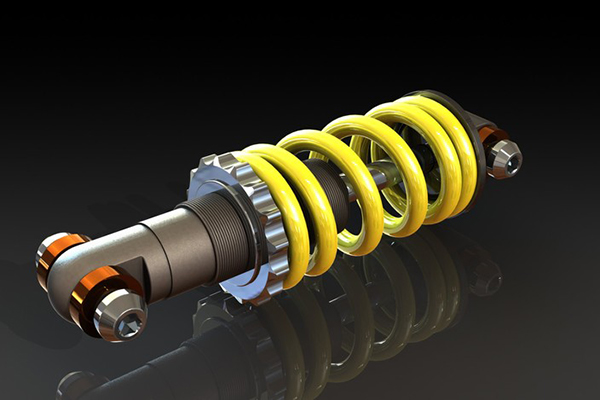

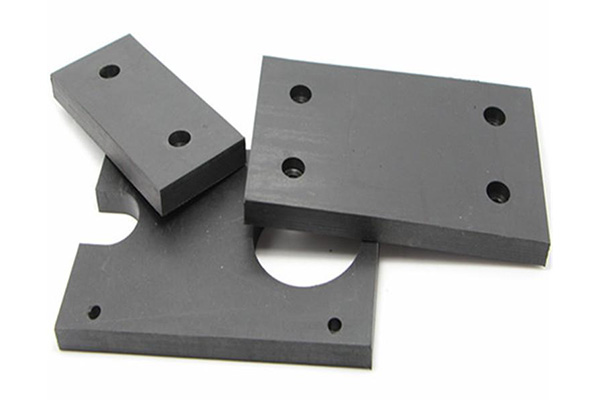

The microcomputer controlled electro-hydraulic servo fatigue testing machine is mainly used to test the dynamic and static mechanical properties of various materials, parts, elastomers, shock absorbers and components.

Enpuda fatigue microcomputer-controlled electro-hydraulic servo fatigue testing machine is mobile and flexible, the beam moves downwards, and the sample holder is locked by button operation.

Adopt advanced hydraulic servo drive technology to load, high-precision and high-resolution dynamic load sensor, magnetostrictive displacement sensor, sample force value and displacement.

The all-digital measurement and control system realizes closed-loop control of force, displacement, and deformation. The test software adopts English operation interface, powerful data processing capabilities, and automatic storage, display and printing of test conditions and test results.

It is an ideal cost-effective fatigue test system for scientific research institutes, metallurgical construction, national defense industry, colleges and universities, aerospace, rail transit and other industries.

Testing standard

Performance features / advantages

| 1. Test machine host: column, base, beam constitute a closed frame structure, frame stiffness, no reverse clearance, good stability. The outer surface of the column is electroplated with hard chromium, the servo actuator (oil cylinder) is placed downward, and the piston design of double acting oil cylinder is adopted. The sample clamping adjustment is convenient and flexible. |

| 2. Key components: adopt international famous brands such as MOOG servo valve of the United States, DOLI controller of Germany, Buer oil pump of Japan, Shiquan sensor of USA, displacement sensor of MTS company of USA, etc. |

| 3. Hydraulic servo pump station: adopt no leakage mute technology, stable pressure output, no fluctuation, low noise, good heat dissipation effect, high filtering accuracy, automatic protection of pressure overload and oil temperature over temperature. |

| 4. Control mode: force, displacement and deformation PID closed-loop control, and can realize smooth and undisturbed switching of any control mode. |

| 5. Test software: it is suitable for the operation and control system under the windows test platform. It can control the test system to complete all kinds of dynamic and static mechanical property tests, such as metal tensile, compression, bending, low cycle and metal fracture mechanical tests. And it can complete all kinds of test management, data storage, test report printing and other functions independently. |

| 6. Test waveform: sine wave, triangle wave, square wave, random wave, sweep frequency wave, combined waveform, etc. |

| 7. Protection function: it has alarm and shutdown functions such as blockage of oil circuit, over temperature, low liquid level, overload of hydraulic system, overheat of motor, preset fatigue times and fracture of test piece. |

Key Parts

1. Optional German DOLI company EDC-I52 fully digital servo controller

2. Use American Interface high-precision dynamic force sensor

3. American MOOG servo valve

4. American MTS magnetostrictive displacement sensor

5. Optional Hydraulic Fixture

6. Enpuda produces hydraulic silent hydraulic servo oil source (powertrain) Low noise, stable operation, excellent durability and long life

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for OEM Factory for Tearing Fixture - Electro hydraulic servo dynamic fatigue testing machine – Enpuda , The product will supply to all over the world, such as: Naples, Latvia, New York, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.