A test to measure a series of properties of materials under tensile load, also called tensile test. It is the basis for material mechanical properties testing

One of the methods, mainly used to check whether materials meet the specified standards and study the performance of materials.

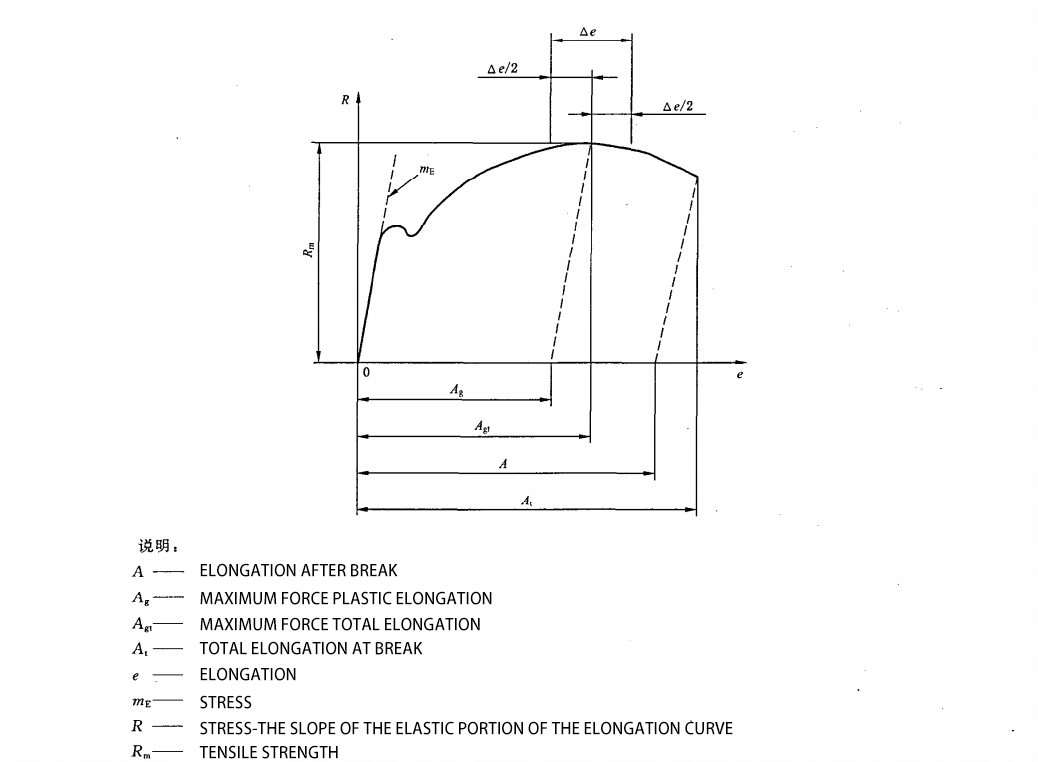

Tensile testing can measure a series of strength indicators and plasticity indicators of materials. Strength usually refers to the ability of a material to resist elastic deformation, plastic deformation and fracture under the action of external forces. When a material is subjected to a tensile load, the phenomenon that the load continues to undergo significant plastic deformation without increasing the load is called yielding. The stress at which yield occurs is called the yield point or physical yield strength. There are many materials that have no obvious yield point. The stress value when the residual plastic deformation of the material is 0.2% is usually regarded as the yield strength, which is called the conditional yield limit or conditional yield strength. The maximum stress value that a material reaches before breaking is called tensile strength or strength limit.

The figure below shows the curve of a metal material when it is stretched and broken:

Plasticity refers to the ability of a metal material to plastically deform under load without damaging it. Commonly used plasticity indicators are elongation and cross-section.

Shrinkage. Elongation, also called elongation, refers to the percentage of the ratio of the total elongation to the original length after the material sample is broken under tensile load. It is expressed as δ.

Show. Shrinkage of area refers to the percentage of the reduced area of the material sample after being broken by a tensile load to the original cross-sectional area, expressed as ψ

express.

Tensile tests were performed on a materials testing machine. Testing machines come in mechanical, hydraulic, electro-hydraulic or electronic servo types. The sample type can be a full cross-section of the material, or it can be processed into a round or rectangular standard sample. Some physical samples such as steel bars and wires generally do not need to be processed and their full cross-sections are maintained for testing.

Post time: Mar-19-2024