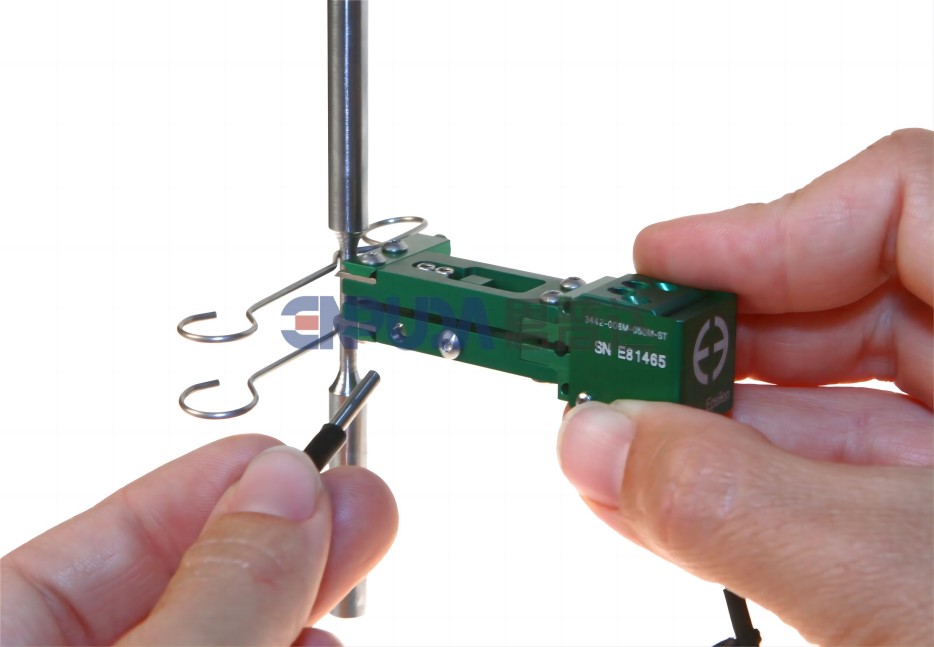

Extensometer is a sensor for measuring specimen deformation, which is mainly composed of strain gauge, deformation transfer rod, elastic element, limit marker bar, cutting edge and clamping spring.

When measuring deformation, the extension meter is attached to the specimen, and the blade contacts the specimen to feel the elongation within the distance between the two blades. The elastic element is strained by the deformation rod, and the strain gauge converts it into the resistance change, and then converts it into the voltage signal with the appropriate measurement amplifier circuit.

In the high temperature environment box, the whole experimental environment is higher at this time the need for high temperature extensometer, high temperature without cooling extensometer – the temperature can reach 700℃; The extensor adopts a high temperature capacitance sensor, and the environmental chamber is installed on the main machine of the testing machine. The extensor can work at the maximum temperature specified in the environmental chamber. It is especially suitable for measuring deformation in tensile, compression or cyclic tests of composite materials, metals and high temperature polymers.

The extensometer is supplied with a DT6229 controller. The extensometer is factory calibrated and the analog signal standard output voltage is 0 to 10V DC. The system offers enhanced features, including high-speed signal output, built-in calibration and tare weighing, analog and digital filtering, and more. The extender can be easily connected to the test machine controller, directly to the data acquisition system and chart recorder, or directly to a personal computer.

Its main parameters are as follows:

Analog output:

User specified, generally +/-5 V DC or +/-10V DC

Digital output:

24-bit high-speed Ethernet output with built-in web interface

Linearity:

11-point linearization, generally ≤ 0.1% of full scale

Resolution:

<55FPM(0.006% of full scale)4kHz,<6PFM(0.0006% of full scale)100Hz

Cycle test:

Generally >25Hz, the use of small stroke units can reach 100Hz,0.5mm stroke

Analog filter:

100Hz analog and 2Hz-3kHz digital filters are available

Temperature range:

The ambient temperature reaches 700℃

Temperature sensitivity (increased):

<100 PFM /°C(0.01%FS/°C)

Temperature sensitivity (compensation):

20 FPM/°C(0.002%FS/°C)

Sensor cable:

0.7m three-axis high temperature cable, 1.5m room temperature extension cable

Standard fast clamping device:

The maximum diameter of the round specimen is 15mm; Flat specimen width 50mm thickness 6.35mm; Flat specimen width

19mm, thickness can be from 6.35mm to 12.5mm

Operating force:

Generally less than 100g

Setting:

Recommended for dry air, inert/non-corrosive gas or vacuum temperature test

The high temperature non-cooling extender meets the accuracy requirements of ASTM standard B-1, and can be certified by ISO9513 standard 0.5 according to the requirements. It is small in size and light in weight, and has better performance in high frequency test, which can reach 100Hz. At the same time, the intuitive visual operation interface is convenient for users to calibrate and data acquisition.

Post time: Apr-15-2024

.png)