Recently, Dr. Li Weilun, CEO of Zwick Group, and his delegation visited to deepen the cooperation between the two sides in technology and market, and jointly explore how to utilize advantageous resources to strengthen the overseas market expansion of testing machines.

Driven by the wave of globalization, cross-border cooperation has become a key strategy for enterprises to explore international markets and enhance their core competitiveness. At this meeting, our company presented its recent major achievements and project results. The following are the specific contents:

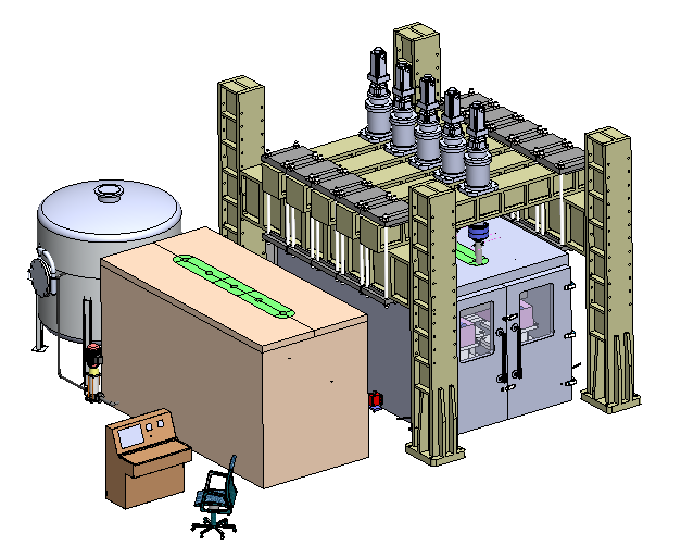

Zhanjiang Bay Laboratory Hanging Network Process System Test Platform: This project has invested over 10 million yuan and uses visual full field strain measurement technology combined with three-dimensional in-situ dynamic control function for mesh stress-strain, creep resistance, dynamic fatigue life, and fracture testing. Vertical concentrated loads are applied at the center of the mesh to simulate the effects of waves and ocean currents on the mesh., Study the intrinsic relationship between fishing net damage, creep, and tension level, find a reasonable range of pre tension, and form a safe and reasonable research system for hanging net technology.

Dr. Li commented, "Studying the intrinsic relationship between damage, creep, and tension levels in fishing nets is crucial for the development of marine fisheries. Mistakes in the design process can cause breakage of nets and escape of aquaculture resources, resulting in significant economic losses. It is a very necessary scientific research equipment for deep-sea aquaculture.

In recent years, with the rapid development of the testing machine industry market, the trend of homogeneous competition in the market has become increasingly prominent. Today, as the values of environmental protection, energy conservation, and efficient production are increasingly valued, we particularly emphasize the green performance and energy efficiency of our products. To this end, we launched a silent hydraulic servo oil source system in 2018, which adopts our company's independently developed servo control technology and hydraulic adaptive PID algorithm, perfectly adapts to the pressure and flow required during testing, and achieves the characteristics of silence and energy saving. The pressure output is stable, without fluctuations, the noise is below 65 decibels, the energy consumption is low, and the heat dissipation effect is good. At the same time, a remote mobile app is configured to monitor the pressure, flow rate, oil temperature, motor operation status, etc. in real time, ensuring the overall safety and smooth operation of the oil source. Compared with constant current and constant voltage products, the energy-saving rate can reach up to 80%, which is currently a key national promotion and application of energy-saving and environmental protection technology.

We adhere to technological innovation as the core driving force and market demand as the development direction, committed to providing customers with differentiated solutions. Our goal is to meet customers' diverse testing needs, enhance their experience, and strengthen their market competitiveness through technological innovation and customized services.

With the continuous deepening of global economic integration, our company will always adhere to the development concept of learning and progressing, and advancing with the times. In the current rapid development of science and technology, we will continue to learn and keep up with cutting-edge technology, and work with industry leaders to provide mechanical testing Bring new vitality to the field!

Post time: Nov-13-2024