Factory supplied Torsional Fatigue Test Equipment – High and low temperature electronic universal testing machine – Enpuda

Factory supplied Torsional Fatigue Test Equipment – High and low temperature electronic universal testing machine – Enpuda Detail:

APPLICATION AREA

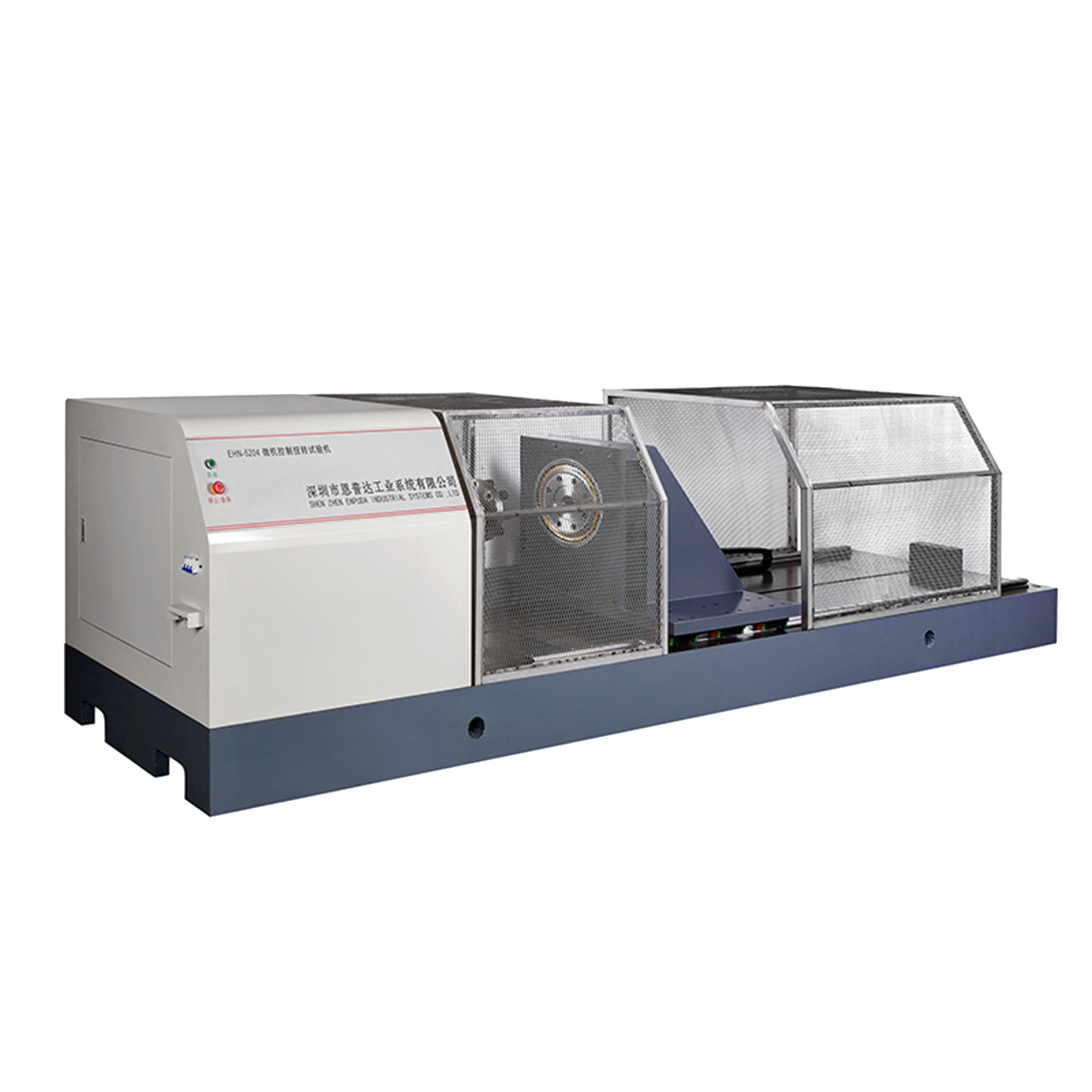

The computer-controlled electronic universal testing machine is mainly used for testing the mechanical properties of metals, non-metals, composite materials and products such as tensile, compression, bending, shearing, tearing, peeling, etc. Complete the environmental simulation test at the corresponding temperature.

Panasonic full-digital AC servo controller is used to control the high-precision, high-response frequency Panasonic AC servo motor, drive the arc toothed synchronous belt deceleration system, and drive the lead screw to rotate and load through the synchronous toothed belt to ensure high transmission system efficiency. Low noise, stable transmission, high transmission precision, long working life, and guarantee speed accuracy within ±0.5%.

The test box is installed with guide rails, which can be moved back and forth to meet the requirements of high and low temperature environments and conventional tests. It has a front-opening sealing device with a visual window, which not only ensures the convenience of use, but also achieves accurate measurement data. It consists of a box, a high temperature heating system, a liquid nitrogen refrigeration system, a temperature controller, an extension rod, a mobile bracket, and a water cooling system.

The high and low temperature electronic universal testing machine is widely used in various industries and is a commonly used testing equipment in enterprises, scientific research units, colleges and universities, engineering quality supervision stations and other departments.

Customized service / Test standard

We not only provide standardized machines, but also customize machines and LOGO according to customer requirements. Please tell us your requirements and we will try our best to meet your needs.

Please provide the test standard you need to our company, our company will help you customize the test machine that meets the test standard you need

Testing machine standard

1. It is manufactured according to GB / t2611-2007 general technical conditions for testing machines and GB / T 16491-2008 electronic universal testing machines;

2. Verification and acceptance shall be carried out according to GB / t12160-2002 “provisions for extensometers for uniaxial test” and GB / t16825-2008 “inspection of tensile testing machines”;

3. It is applicable to GB, JIS, ASTM, DIN and other standards.

Testing standard

Performance features / advantages

| 1. Exquisite and elegant design: our company has always attached great importance to the appearance of products and developed many products comparable to foreign models. Some of the testing machines have been protected by national appearance patents; |

| 2. Arc tooth synchronous belt deceleration system: it has the advantages of high efficiency, long life, low noise and maintenance free; |

| 3. High precision ball screw loading: stable loading, long service life, good long-term stability and energy saving; |

| 4. It adopts the new generation DSC chip system newly developed by the company: it is the most advanced controller with the highest integration degree and the highest control speed in China; |

| 5. User operation interface: simple and reliable human-computer interaction interface and data processing interface to complete different experimental requirements selected by users; |

| 6. Open data structure: both result parameters and process data can be called randomly by users, which is very convenient for scientific research and teaching; |

| 7. User self editing scheme and report function: it can edit special scheme according to all standards at home and abroad, which is convenient for real-time calling; data can be imported into EXCEL form to facilitate user’s post-processing; |

| 8. A variety of protection measures: such as electronic limit protection, over-current, over-voltage and other power links of electrical protection, software overload, over displacement protection, mechanical mandatory safety limit protection, etc. |

Key Parts

1. Electronic universal testing machine remote control

2. Special high temperature box for electronic universal testing machine

3. High-precision ball screw, high precision, stable operation and long service life

4. SSRT high temperature fixture(Design according to the actual needs of users)

5. High-precision load sensor, American Transcell brand

6. Using Japanese Panasonic servo motor, stable and durable performance, high precision

7. Liquid ammonia refrigeration system

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for Factory supplied Torsional Fatigue Test Equipment – High and low temperature electronic universal testing machine – Enpuda , The product will supply to all over the world, such as: Ecuador, Casablanca, Armenia, Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.