Factory Price Automobile Leaf Spring Fatigue Testing Machine - Electronic dynamic testing machine – Enpuda

Factory Price Automobile Leaf Spring Fatigue Testing Machine - Electronic dynamic testing machine – Enpuda Detail:

APPLICATION AREA

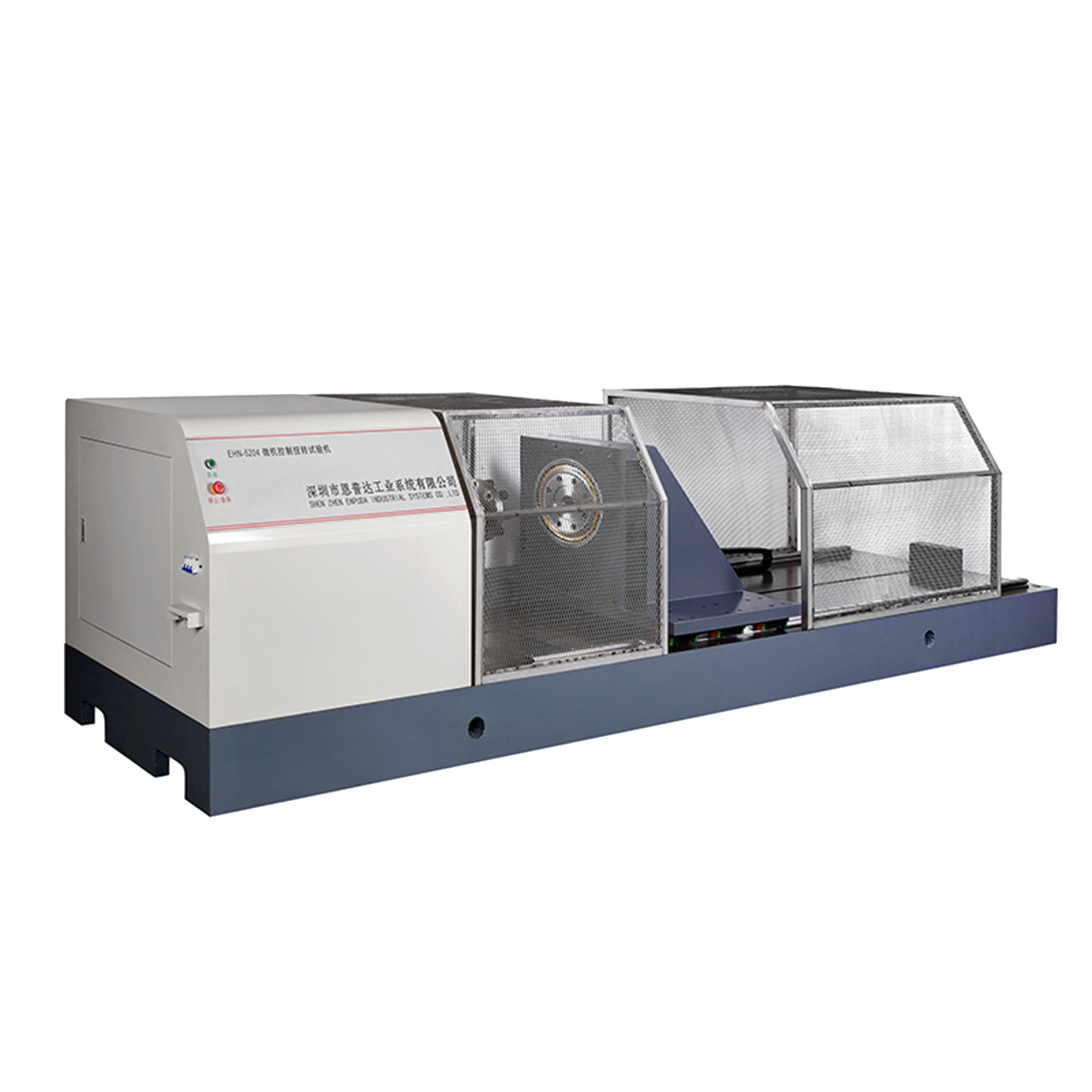

Microcomputer-controlled electronic dynamic fatigue testing machine is mainly used for dynamic and static mechanical performance testing of metal, non-metal, composite materials and structural adhesives, lithium battery core poles and other products.

Enpuda microcomputer-controlled electronic dynamic fatigue testing machine is flexible and convenient to operate, and the electric movable beam rises and falls.

It adopts advanced electric cylinder drive technology to load, high-precision dynamic load sensor and high-resolution magnetostrictive displacement sensor to measure the force value and displacement of the sample.

The all-digital measurement and control system realizes closed-loop control of force, displacement, and deformation. The test software adopts English operation interface, powerful data processing capabilities, and automatic storage, display and printing of test conditions and test results.

The testing machine is an ideal cost-effective fatigue testing system for scientific research institutes, metallurgical construction, national defense industry, colleges and universities, aerospace, rail transit and other industries.

Customized service / Test standard

We not only provide standardized machines, but also customize machines and LOGO according to customer requirements. Please tell us your requirements and we will try our best to meet your needs.

Please provide the test standard you need to our company, our company will help you customize the test machine that meets the test standard you need

Testing standard

Performance features / advantages

| 1. The electronic servo and DDR torque motor drive technology has the advantages of high efficiency, long service life, low noise and maintenance free; |

| 2. The testing machine adopts “horizontal floor structure” with good dynamic stability, and the upper and lower parts of the test bench are convenient, random, safe and reliable; |

| 3. The parameters required by different tests, such as torque, frequency and angle, can be set and displayed on the computer screen, and the process of the test can also be called and inquired at any time; |

| 4. User interface: the test software can be operated under Windows system, and the microcomputer system can complete the test setting, working state control, data acquisition and operation processing. Simple and reliable human-computer interaction interface and data processing interface can complete different experimental requirements selected by users, display and print test results; |

| 5. Open data structure: both result parameters and process data can be called randomly by users, which is very convenient for scientific research and teaching; |

| 6. A variety of protection measures: sample damage, tooling fracture and equipment failure, automatic stop test and alarm, in the automatic control test process, the tester has overload, over angle, over temperature, electronic limit protection, over-current, over-voltage and other power links of various electrical protection, software overload, mechanical mandatory safety limit protection, etc. |

Test Standard

Comply with GB/T 9370-1999 “technical conditions of torsion testing machine”, GB/T10128-2007 “torsion test method of metal at room temperature” and JJG 269-2006 “verification regulation of torque testing machine” and other standards.

Comply with GB, JIS, ASTM, DIN and other standards.

Key Parts

1. Optional German DOLI company EDC-I52 fully digital servo controller

2. Use American Interface high-precision dynamic force sensor

3. American MOOG servo valve

4. American MTS magnetostrictive displacement sensor

5. Optional Hydraulic Fixture

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Factory Price Automobile Leaf Spring Fatigue Testing Machine - Electronic dynamic testing machine – Enpuda , The product will supply to all over the world, such as: Bangkok, Bandung, Mumbai, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.