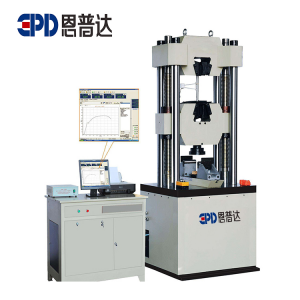

Electro-hydraulic servo universal testing machine

| product name | Electro-hydraulic servo universal testing machine | |||||

| Customized service | We not only provide standardized machines, but also customize machines and LOGO according to customer requirements. Please tell us your requirements and we will try our best to meet your needs. | |||||

| Core keywords | Electro-hydraulic static universal testing machine Static universal testing machine | |||||

| Product function and purpose | Mainly used for the test of metal tensile, compression, bending and other mechanical properties. It can realize the tests of constant rate loading, constant rate deformation, and constant rate displacement, and can realize three control methods of force, displacement and deformation in one test. , There is no impact on the conversion of various control methods. The test parameters are collected by computer and processed by software. According to GB, JIS, ASTM, DIN and other standards, the maximum test force value, breaking force value, yield strength, upper and lower yield points, tensile strength, various elongation stress, various Parameters such as elongation, compressive strength, elastic modulus, etc., automatically generate test report format, and can print test report curve at any time. | |||||

| Performance features / advantages | 1. The key components adopt international brands: American MOOG servo valve, Japanese Fujitsu oil pump, American Sequan sensor, American EPC displacement sensor, etc.; | |||||

| 2. Double-space structure, the upper part is a tensile space, and the lower part is a compression space, which is convenient for testing without conversion; it adopts semi-closed structure jaws, which has good rigidity, high strength, safety and durability; | ||||||

| 3. The use of integrated silent oil source and hydraulic follow-up valve technology reduces energy consumption and heat generation in the hydraulic system. The hydraulic oil can be used for a longer time, which is comfortable and environmentally friendly; | ||||||

| 4. The new generation EHSC-8000 measurement and control system, which is a controller based on the DSC platform, is the DSC controller with the most advanced, highest integration and highest control speed used in the material testing industry so far, with great performance DSP chip system leading domestic counterparts; | ||||||

| 5. Adopt advanced electronic technology and hydraulic loading computer for data collection and processing; powerful test software function has curve data storage and curve amplification functions, equipped with data interface for easy analysis; supports multiple languages and can switch freely between Chinese and English; | ||||||

| 6. The system has fast response speed, high control accuracy, strong anti-pollution ability and high reliability; | ||||||

| 7. Complete protection functions: It is equipped with alarm and shutdown functions such as oil circuit blockage, over temperature, low liquid level, hydraulic system overload, motor overheating, and test force overload. | ||||||

| 产品规格参数 | Model of testing machine | EH-8305 Four pillars | EH- 8605 Four pillars | EH- 8106 Six pillars | EH-8206 Six pillars | EH-8506 Six pillars |

| Maximum load(kN) | 300 | 600 | 1000 | 2000 | 5000 | |

| Load accuracy | Better than the indicated value ±1%、±0.5% | |||||

| Measurement range of test parameters | 1~100%FS(full range),It can be extended to 0.4~100%FS | 2~100%FS(full range) | ||||

| Displacement and deformation accuracy | Better than the indicated value ±1%、±0.5% | |||||

| Speed range(mm/min) | 0.01~50( It can be extended to 100) | |||||

| Resolution of test parameters | The load and deformation are not classified and the resolution remains unchanged ±1/350000FS(full range) | |||||

| Tensile / compression test space(mm) | 620/550 | 690/620 | 620/580 | 700/600 | 650/600 | |

| Test width of left and right columns(mm) | 500 | 570 | 600 | 600 | 650 | |

| Clamping diameter of round specimen(mm) | Φ10~32 | Φ13~40 | Φ14~45 | Φ20~70 | Φ20~80 | |

| Clamping thickness of plate specimen(mm) | 0~15 | 0~30 | 0~40 | 0~50 | 0~80 | |

| Motor power(kW) | 1.5 | 2.2 | 2.2 | 5.5 | 11 | |

| Overall dimension (length × width × height) mm | 800×500×1950 | 950×630×2260 | 980×650×2220 | 1200×850×2900 | 1350×950×3200 | |

| Main engine weight(Kg) | 2000 | 2500 | 3300 | 5500 | 10000 | |

| Remarks: The company reserves the right to upgrade the instrument without any notice after the update, please ask for details when consulting. | ||||||

| According to the standard | 1. Comply with GB/T 2611-2007 "General Technical Requirements for Testing Machines" and GB/T 16826-2008 "Electro-hydraulic Servo Universal Testing Machines" standards; | |||||

| 2. Meet the requirements of GB/T 228-2010 "Metal Material Room Temperature Tensile Test Method", GB/T 7314-2005 "Metal Material Room Temperature Compression Test Method", GB/T 232-2010 "Metal Material Bend Test Method"; | ||||||

| 3. Suitable for GB, JIS, ASTM, DIN and other standard requirements | ||||||

Write your message here and send it to us